Alumina is reduced to metallic aluminum in an electrolytic cell called a "pot", which is made up of two main parts - one serves as the anode or positive electrode of the cell, and the other, as the cathode or negative electrode. The anode consists of a block of carbon formed by baking coke and pitch, while the cathode is found in the carbon lining of a large steel container located under the anode. This lining is formed by baking metallurgical coke and pitch.

The space between the anode and the cathode is filled with an electrolytic bath of sodium aluminum fluoride, or cryolite. The electrolyte is heated to about 980°C, at which point it melts and the alumina is added and dissolved. An electric current is then passed through the mixture to split the alumina into molten aluminum metal at the cathode and carbon dioxide at the anode.

This Hall-Héroult process was invented in 1886 and has since been steadily improved. Currently, it takes about 2 tonnes of alumina to produce 1 tonne of aluminum metal.

Smelting consumes huge amounts of electricity because of the high temperatures that must be generated. Typically, the electrolysing current is delivered at a high amperage and on average, it takes almost 14,171 kwh of electricity to produce 1 kg of aluminum from alumina compared with XinRen's average of 13,727 kwh in 2009. In addition, the smelting process is continuous as the metal in the pots cannot be allowed to solidify. Not surprisingly, most plants around the world are located in areas where there is ample access to inexpensive energy.

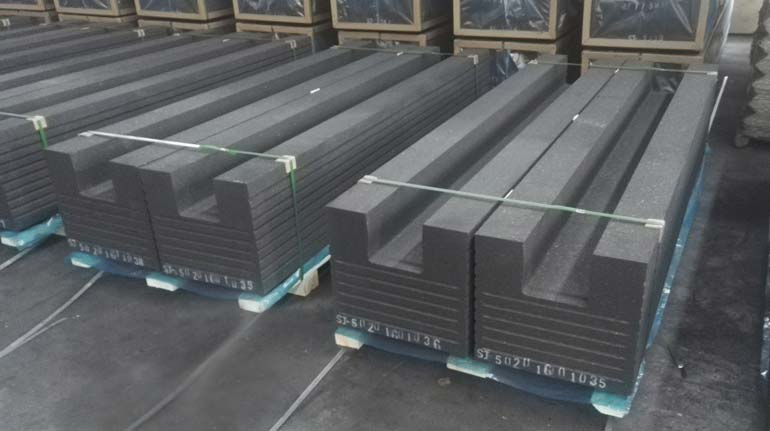

A cathode block is a negative electrode and is used in the lining of aluminium reduction cells. A cathode block has the properties of superior electrical and thermal conductivity, high chemical and bulk stability, as well as high strength in electrolysis under high temperature. Sidewall blocks, ramming pastes, and special glues round out the cathode product portfolio, providing complete custom-made solutions to optimally fit the requirements in the aluminium smelter.

Compared with conventional amorphous carbon or graphitic blocks, our fully graphitized cathode block offers high thermal and electrical conductivity and higher resistance against thermal shock and contributes to energy savings, higher productivity, and longer pot life.

English

English

Persian (Iran)

Persian (Iran)